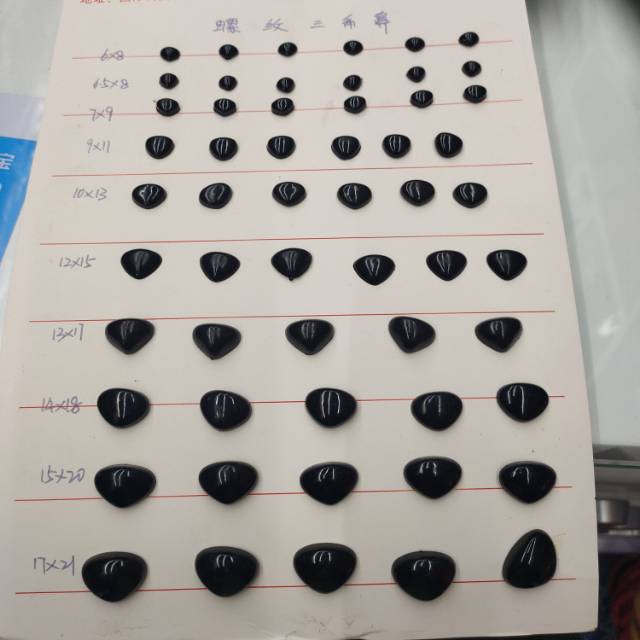

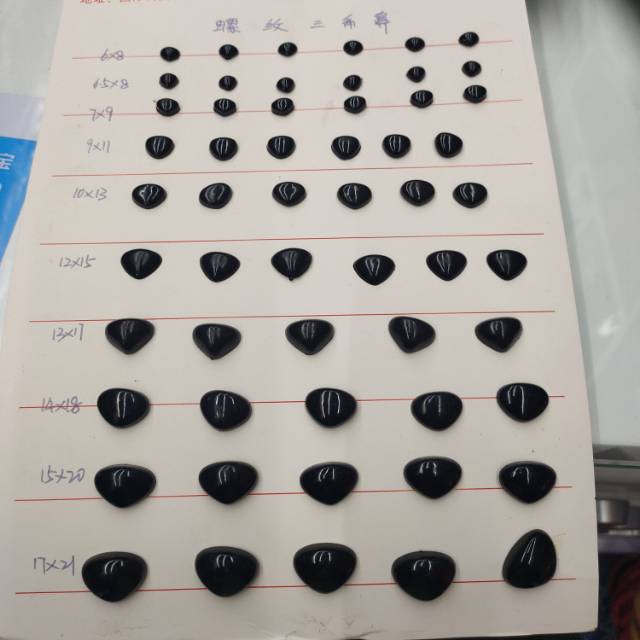

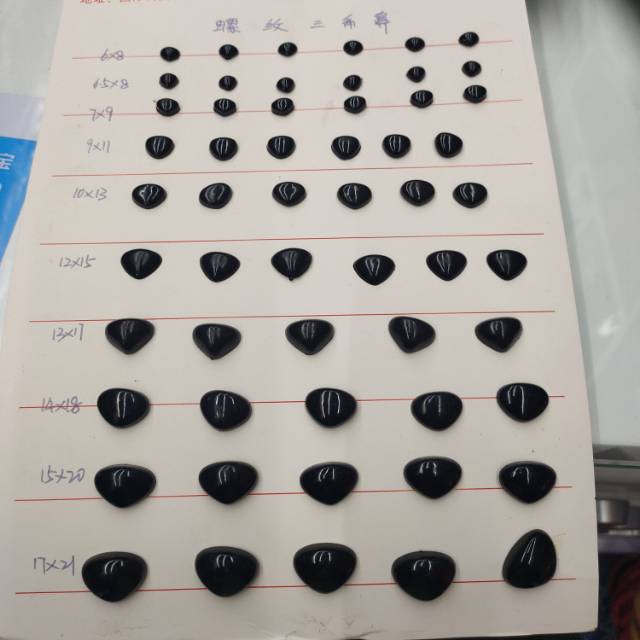

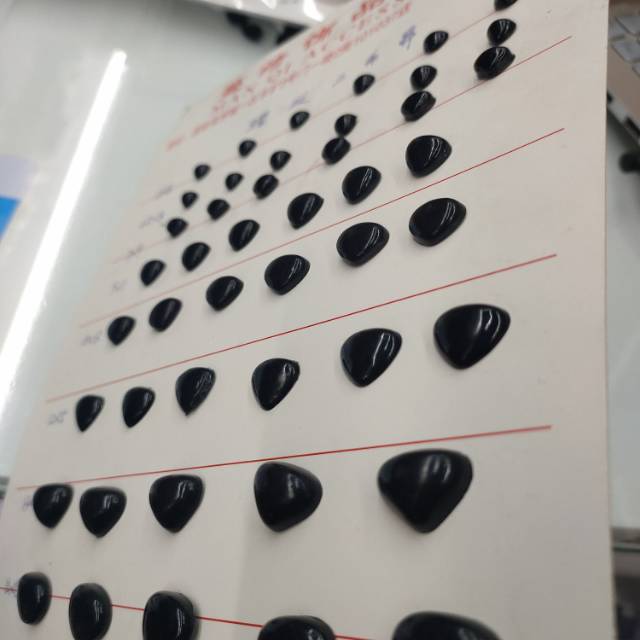

The original design intention of the threaded triangular nose and eye fittings: an innovative solution to diverse needs

In the face of increasingly complex application scenarios in the market, traditional fixtures have been difficult to meet the changing needs. Designers in-depth research customer needs, combined with the latest engineering and technological achievements, developed this both beautiful and practical threaded triangular nose and eye accessories. Through detailed analysis of its design concept and technical parameters, it reveals why it can stand out in many similar products.

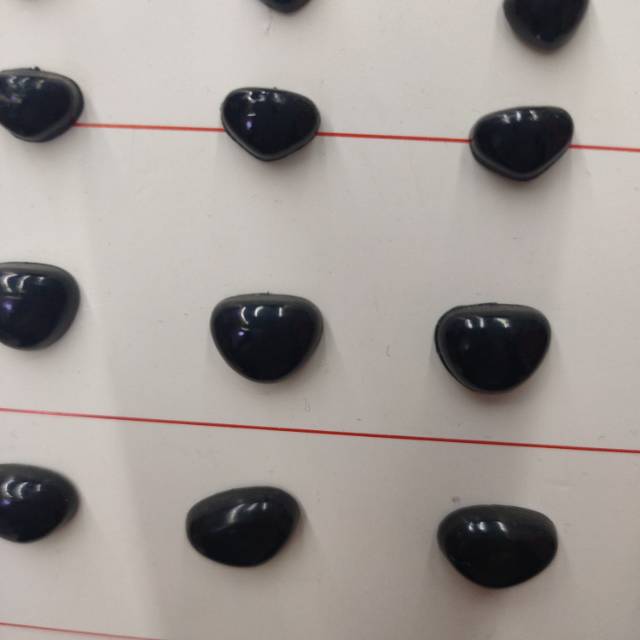

Designers realize that in many engineering projects, existing fixed solutions often have limitations and cannot flexibly cope with various complex construction environments. To this end, they decided to break the regular mode of thinking and introduce a new geometric form-the thread triangle structure. This unique shape not only enhances stability, but also provides a larger contact area, thereby improving tensile strength and wear resistance. In addition, the accessory adopts an internal and external double-layer thread design, which can better adapt to different types of working conditions and ensure a long-term and reliable use experience.

Behind excellent performance: the dual guarantee of material science and precision technology

An excellent mechanical parts can not be separated from high-quality raw materials and exquisite processing skills. The article will focus on the unique alloy material used to produce this accessory and its excellent characteristics, and how to use advanced manufacturing equipment to achieve high-precision molding. It will also discuss the importance of the quality inspection process and how strict factory standards ensure that each part meets the most high quality requirements.

In order to give the threaded triangular nose and eye fittings extraordinary durability and reliability, the manufacturer chose high-strength stainless steel as the main raw material. This special alloy has extremely high corrosion resistance and good ductility, and can maintain stable performance even under extreme operating conditions. Not only that, the finished product after a series of processes such as precision casting and cold forging has a smooth surface and uniform internal organization, which greatly reduces the risk of fracture due to stress concentration.

each batch of threaded triangular nose and eye fittings need to go through strict quality inspection procedures, from appearance size measurement to mechanical performance testing, any link can not be careless. Only fully qualified products can be packaged and shipped to customers around the world. It is such a meticulous attitude has created a good reputation for the brand, but also for the majority of users to bring more secure and assured choice.

Performance in practical application: Witness efficient and stable field operation ability

In order to verify the superior performance of this product, we invited many industry experts to conduct a comprehensive test on it and put it into use in a real environment. From busy urban construction projects to large mechanical equipment assembly lines, no matter how harsh working conditions can not stop its outstanding performance. This section will record the user's first-hand evaluation feedback on the accessory based on specific project examples.

At a high-rise construction site, workers need to quickly and accurately complete the connection tasks between a large number of reinforced concrete components. The common welding methods used in the past are inefficient and easily lead to safety hazards. Since the adoption of our threaded triangular nose and eye fittings, the entire construction progress has been significantly accelerated and the work efficiency has been greatly improved. More importantly, because the accessory has a strong self-locking function, it will not easily loosen and fall off even if it is shocked by the outside world, which greatly reduces the possibility of accidents.

Another typical case occurred on the assembly line of an automobile manufacturing company. A large number of parts assembly operations are carried out every day, and the requirements for fasteners are very high. After comparison and trial, it is found that this threaded triangular nose-eye accessory has better compatibility and higher installation accuracy than other brands of the same type of competition. Therefore, it was quickly approved by the production line supervisor and officially included in the purchase list.

Flexible adaptation to multiple environments: infinite possibilities brought by strong adaptability

With its unique geometric design and a wide selection of specifications, this accessory can easily meet challenges in different engineering environments. Whether it is indoor small furniture assembly or outdoor large steel structure construction, you can find the most suitable application. We will share several typical application scenarios, including but not limited to successful cases in the fields of bridge construction and ship maintenance.

In the bridge construction project, considering the characteristics of large span and complex stress of the bridge body, the construction unit has selected large-diameter threaded triangular nose-eye fittings to firmly connect the main beams. Thanks to its excellent toughness and large coefficient of friction, it still maintains sufficient safety even in strong wind weather or frequent vehicle traffic. In addition, it is worth mentioning that these accessories can also adjust the angle direction according to the actual situation, so as to facilitate the operation of the later maintenance personnel.

For marine engineering, various lifting tools and auxiliary facilities are often used during the repair and maintenance of ships in docks. At this time, the small and light but strong load-bearing capacity of the threaded triangular nose and eye accessories become the ideal choice. It can be quickly installed and disassembled without damaging the base metal structure, saving a lot of time and cost investment. At the same time, the waterproof and anti-corrosion coating protection measures further extend the service life, and truly save worry and trouble.