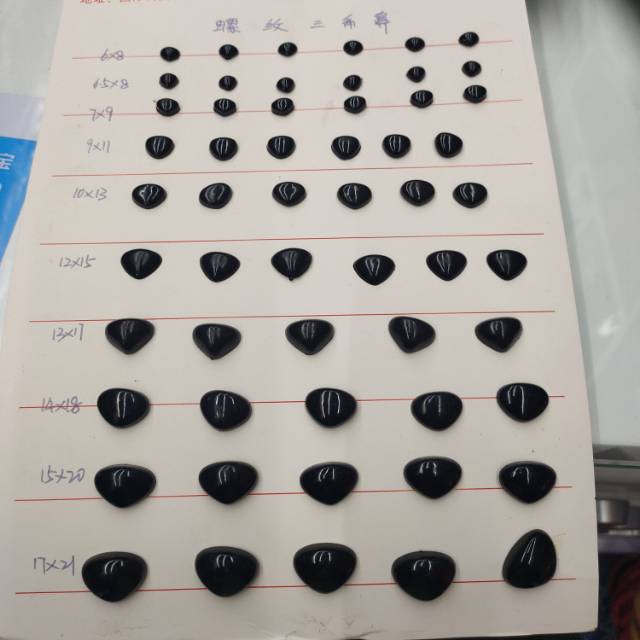

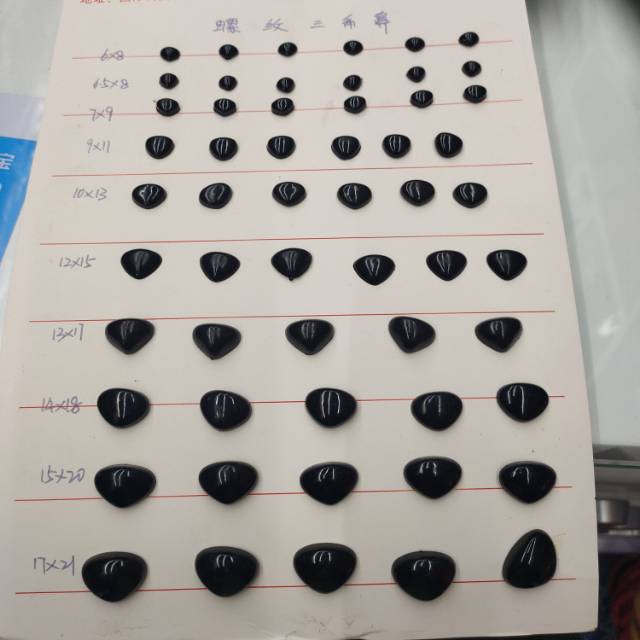

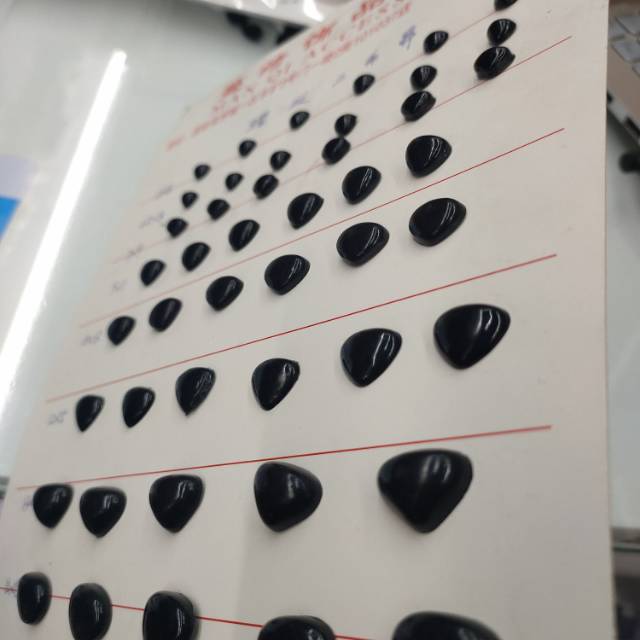

Among the many hardware accessories, there is a low-key but very attractive product-threaded triangular nose and eye accessories. Its simple appearance without losing personality, combined with practicality and aesthetic design, has become an ideal choice for countless designers and craftsmen.

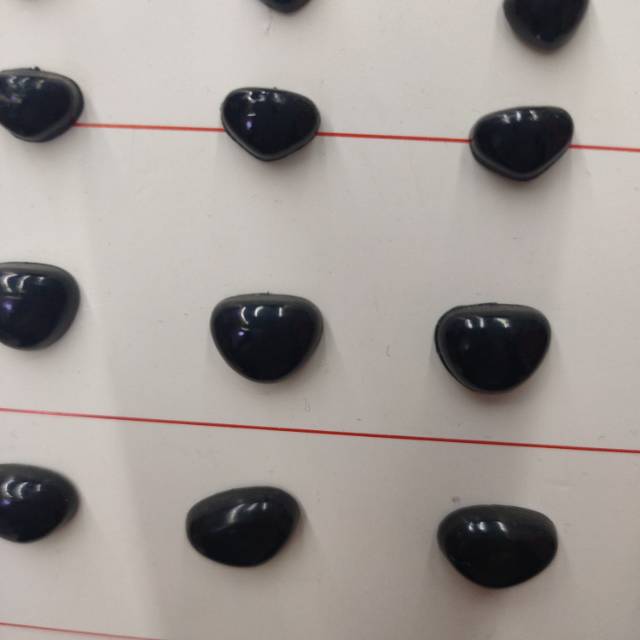

What makes this accessory stand out is its attention to every detail. First of all, it is made of high-quality materials, with extremely high corrosion resistance and wear resistance, and is suitable for various complex environmental conditions. Secondly, the unique triangular shape not only enhances the appearance of the recognition, but also enhances the degree of connection. Compared with the traditional circular nose ring style, this innovative structure can more disperse stress distribution, thereby reducing the risk of fracture.

Despite its small size, the threaded triangular nose and eye fittings are extremely powerful. It can be easily applied to many fields, including but not limited to handmade products, furniture assembly and mechanical engineering construction. By adjusting the matching screw length or aperture size parameter settings, users can flexibly customize the solution according to specific needs.

In recent years, more and more professionals have turned their attention to this special part. For interior decorators, they are used to fix curtain rails or hangers; for jewelers, they can participate in the creation process as part of the chain pendant assembly. It is precisely because of such a wide range of applications and reliable quality assurance that more people are willing to try to incorporate it into their own workflow to experience it.

Let's take a look at some real cases! A well-known DIY blogger used several groups of such accessories to successfully create a set of retro-style bookstick clips, which quickly triggered a heated discussion on the Internet. In another large-scale construction project, the construction team also relied on these seemingly insignificant small objects to complete the precise positioning task of complex pipeline systems.

Of course, there are some key factors to be aware of before buying to ensure that you get the best fit. First of all, there is the problem of specifications and sizes. Please be sure to accurately measure the relevant data of the required installation parts before making a decision so as not to cause errors and lead to abnormal use. Secondly, the difference in visual effects caused by the difference in surface treatment types also needs to be taken into account. For example, the matte black paint version is more stable and heavy, while the electroplated bright silver style is delicate, flexible and energetic.

Finally, I would like to remind you of some suggestions on post-maintenance in order to better extend the service life: avoid contact with chemical solvents to prevent damage to the external coating; Regularly check the loosening of fasteners and repair them in time if necessary to prevent accidental falling off.